Coffee table "Wave"

Coffee table with surfboarding in mind. Spray painted with subtle gradient.

3D printed in 8 hours from PLA + cellulose plastic pellets. There are integrated slots for nuts and screws for easy assembly after manufacturing. We are constantly searching for ways to make printed parts with less post-processing.

READ ARTICLE ON 3DKLASE.LT

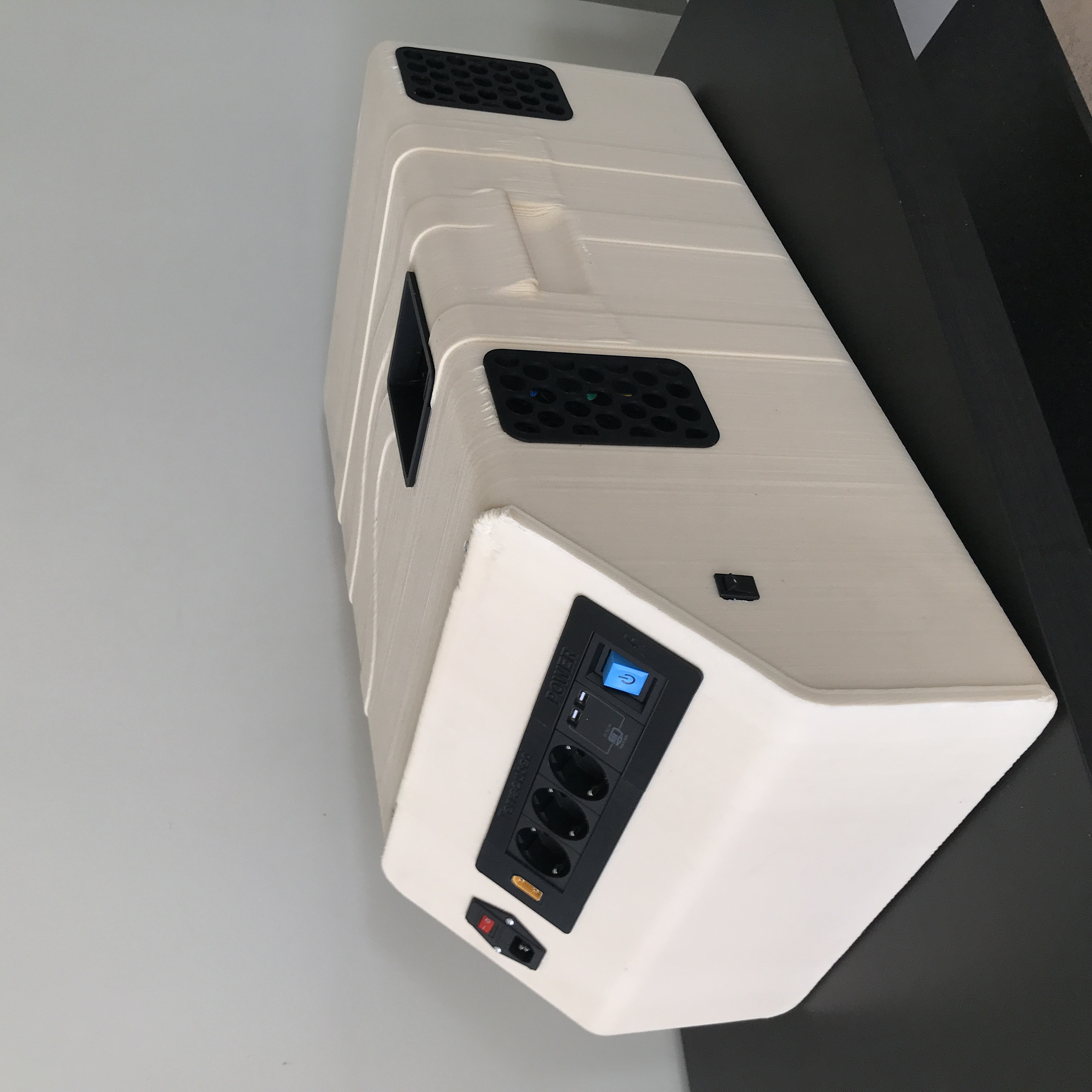

8,5kWh Powerwall - fully working prototype

We have managed to achieve "slide-in" design where pre-assembled battery and inverter pack can easily slide inside the printed case and stay without any movement.

All holes for the cover were printed with bridges or supports which were easily removed after printing, leaving us with everything prepared for the assembly of final components.

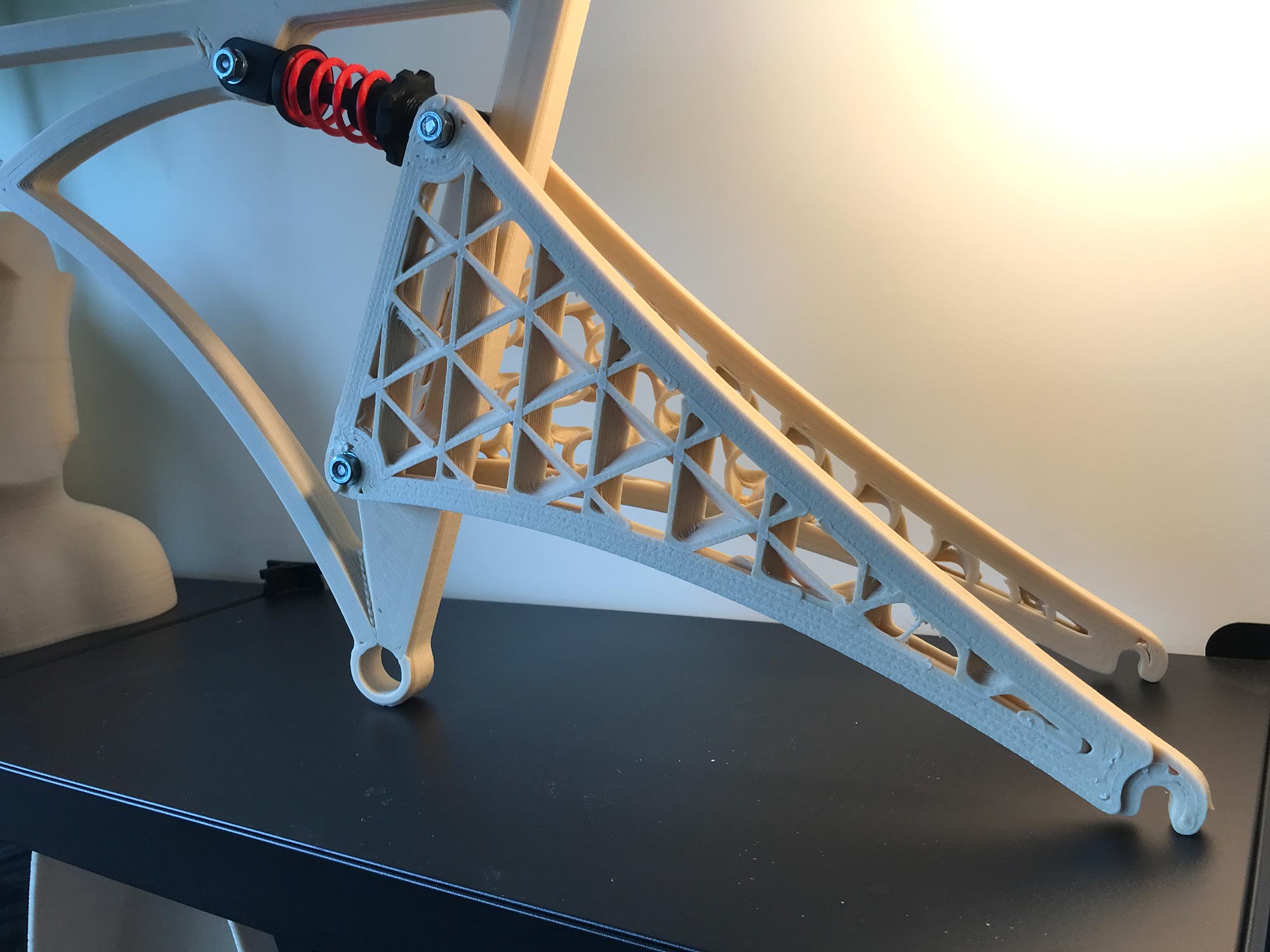

1:1 scale - Mountain bike frame

Our bike frame represents beautiful infill options for any of the projects.

3D printing with solid infill is a "no-go" when trying to stay sustainable. We have managed to achieve spectacular results with different shapes of infills.

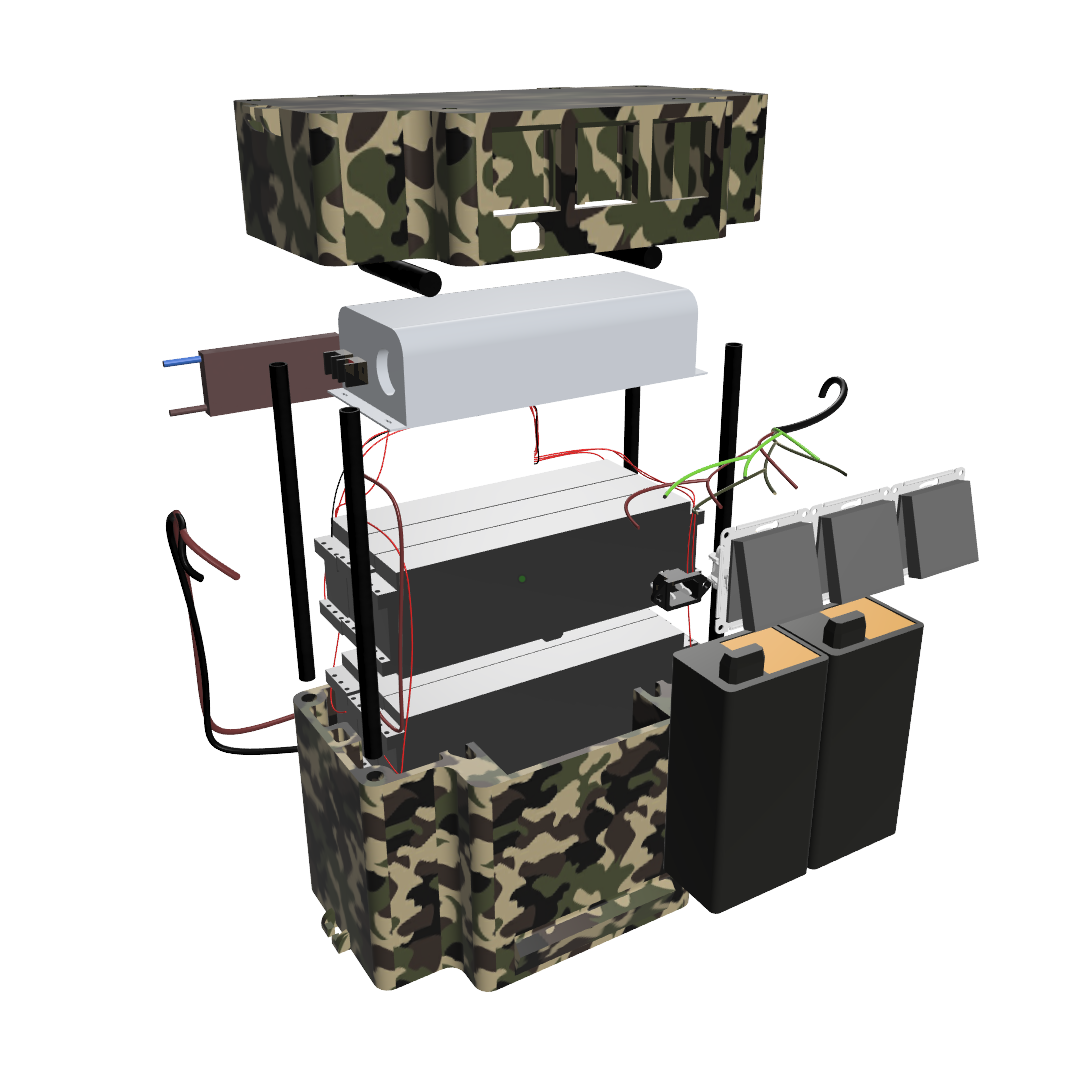

3.5kWh Powerbank - "Apocalypse" concept

Prototyping is fun for us. We are constantly trying to make our dreams reality. After discussions of apocalypse in our office, we've finished with portable heavy-duty powerbank design.

3D model design includes all the required holes, inserts and tolerances for easy assembly. After printing we've put rubber inserts and pre-assembled battery pack inside the case. Then followed tightening of the case. That's all you need for fast iterations of your ideas - just some simple steps when model was thought out beforehand.

UV-C desinfection robot

Self-driven desinfection robot which uses UV-C to properly remove all the bacteria. From idea to reality in less than a month. Case for the robot was printed in two parts which holds each other in place by tight-fit.

As we have made the whole assembly in CAD environment, all the components may be changed or adjusted according to ongoing situation. Supply chain shock or components unavailability is not a big deal when we are able to adapt and change the model for production.

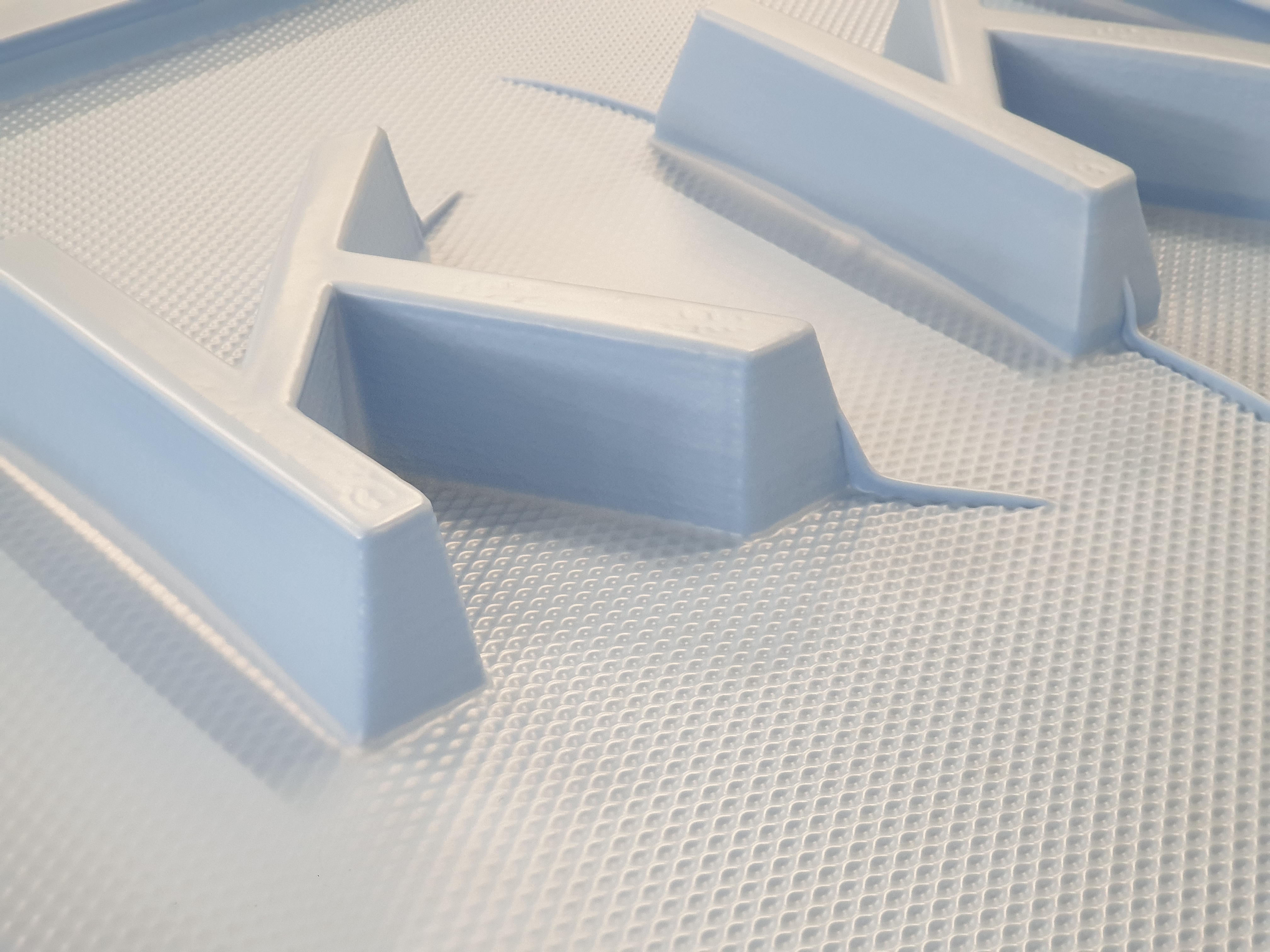

Forms for vacuum forming

Mixing few technologies together is the best way to swiftly adapt and achieve your goals.

Vacuum formed letters at our clients facility provided us some really good insights of what's possible to achieve with Terracubed 3D printer.